The Guide to Buying Cleanroom Swabs

If you have a cleanroom, you understand the importance of meeting stringent requirements. So does Puritan Medical Products. We manufacture our PurSwab line of critical environment (CE) swabs in our ISO 13485:2016-certified and CE-compliant facility to provide the reliable, consistent performance you expect from the end products that you purchase. The question is, what type of swab is best for your specific needs?

As you read through the overview of swab shafts and tips below, you’ll see our PurSwab brand line of swabs offers plenty of choices for cleanroom applications. With these details on our tipped applicators, you can confidently select the cleanroom swabs that best meet your needs.

What are cleanroom swabs?

A cleanroom’s controlled environment must minimize the pollutants such as dust and other airborne particles. However, even the cleanest environments feature materials, systems, and people that can potentially generate microscopic particles despite the best protections. Lessening this emission through careful choice of materials – including cleanroom swabs – is important.

Whether you’re manufacturing sensitive electronics, medical equipment, pharmaceuticals, or other delicate components, you have to be able to trust that your cleaning solutions meet your minimum for allowable particles per cubic meter. Cleanroom swabs are specially formulated to reduce the potential for lint and other residue, among other specialized features.

Understanding the types of cleanroom swabs

Just as there are many types of cleanroom applications, there are cleanroom swabs specially formulated to meet unique needs. These simple tools have two critical components to consider:

- Shaft material: You have several options to choose from when it comes to swab handles, including wood, polypropylene, and paper. This variation allows users to select a material with the appropriate amount of stiffness or give for the task at hand.

- Swab tip: There are far more options available when it comes to the tip of your cleanroom swabs. These range from cotton and compressed cotton to foam, foam over cotton combinations, knitted polyester and microfiber. The option you select will depend upon your need for absorption of cleaning agents or liquid contaminants, allowable abrasiveness and potential for linting, and other features. Some cleanroom swabs’ tips are formulated to offer additional benefits, including chemical resistance or antistatic and electrostatic discharge (ESD) properties.

Choosing the right cleanroom swab handle

Below is a deeper dive into the benefits and applications of each cleanroom swab handle material to help you match the appropriate tool to your application:

Polypropylene shafts

- Molded or extruded options are available

- Can be glass-filled for extra rigidity

- Can be blended with carbon for conductivity

- Can be blended with inherently static-dissipative polymers

Paper shafts

- Compressed

- Stiff

- Biodegradable

- Most often used with compressed cotton/lint-free tips

- Used in manufacturing disk drives

- The paper is stiff, clean, and makes for a “green” tip-to-toe construction

Wood shafts

- Northern white birch

- A “natural” material

- Rigid

- Contains particulates, so not typically recommended for cleanrooms

Choosing the right cleanroom swab tip material

Below, we’ve outlined the benefits and uses of each cleanroom swab tip material to help you match the right properties to your application. However, it is also important to note that many of these swab tips come in varying shapes – including pointed, rectangular, and corkscrew – to aid users in specific cleaning or application tasks.

Knitted Polyester

- Soft, non-abrasive, and lint-free

- Can easily withstand IPA, acetone, and other solvents

- Non-absorbent

- Low particle generation and low non-volatile residues (NVRs)

- Made in a Class 1000 cleanroom

- Ideal for cleaning electronic and communication devices and perfect for instrumentation and medical device manufacturing

Microfiber

- Soft and non-abrasive

- Low particle generation and low NVRs

- Absorbent

- Resistant to normal cleaning solvents, which makes them ideal for removing contaminants and excess materials in fine assembly environments

- The fiber is made from denier thread smaller than polyester

- Suitable for cleanrooms, fiber-optics, and component manufacturing

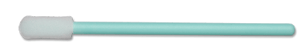

PurSwab foam

- Synthetic – polyurethane foam

- 100 PPI provides good particle entrapment

- Options include open-cell, closed-cell, dissipative, highly absorbent, and chemical-resistant styles

- Non-linting, making it good for removing epoxy residue from connectors, in general cleaning, or as a flux remover

- Thermal edge seals and thermal bonding to the handle helps ensure the sponge-like foam will clean up unwanted particles without releasing any into your environment

Foam Over Cotton

Made from shred-resistant urethane foam over USP  pharmaceutical-grade cotton for the best absorption that performs well when cleaning with solvents

pharmaceutical-grade cotton for the best absorption that performs well when cleaning with solvents

- Friction bond

- Foam over cotton holds up better under vigorous use than stand-alone cotton

- Extra absorption

Chemical-resistant foam

- Made of a unique polymer that stands up to most solvents and aggressive chemicals (including acetone)

- Used for general cleaning, removing and applying adhesives and other solutions

- The slight texture of the foam creates a light abrasion

Antistatic and ESD materials

- To prevent electrostatic discharge (ESD) and static buildup electronics and other sensitive devices should only be cleaned with ESD and/or anti-static swabs

- Designed for working in and around static-sensitive components and parts

- Anti-static applicators are made with an anti-static foam tip and a conductive polypropylene handle or standard wood handle

- ESD applicators are made with anti-static handles and have unique tips, some are made of ESD conductive foam, polyester, cotton, and non-woven materials

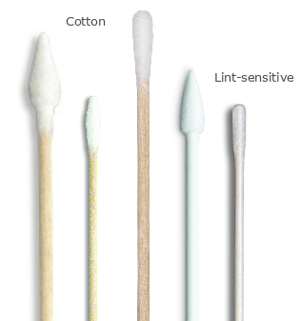

Cotton tips

- “Standard”

- Absorbent, linty

- Soft

- Many configurations possible

- Inexpensive, readily available

- Useful for non-medical applications

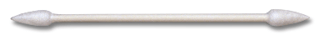

Cotton tips for lint-sensitive applications

- Non-linting and residue-free

- Soft

- Some offered in anti-static packaging

- Typically double-tipped

- Used in HDD manufacturing

- Suitable for cleanrooms

- Smallest tips starting at 2 mm

- Bulb and pointed styles